Duct tape has been around for nearly 100 years, bringing great convenience and efficiency to humans. The reason why tape can stick is that it is coated with a layer of adhesive on the surface, so that the tape can stick to things. The earliest adhesive came from animals and plants. In the 19th century, rubber was the main component of adhesive. In modern times, a wide variety of polymers are used.

According to its efficacy can be divided into: high temperature tape, double-sided tape, insulation tape, special tape, pressure sensitive tape, die cutting tape, different effects for different industry needs, it is an essential thing in all industries.

Definition of tape

With touch and light pressure, the tape can be easily attached to the surface of the adhesive. Tape is a viscoelastic polymer that has both liquid and solid properties. Therefore, compared with glue, adhesive tape does not need curing process during bonding, which can save time. The use of adhesive tape is very wide, in addition to the daily office adhesive tape products, adhesive tape in automobile, electronics, paper printing, construction, home appliances, new energy, rail transit and other industrial fields also have numerous applications.

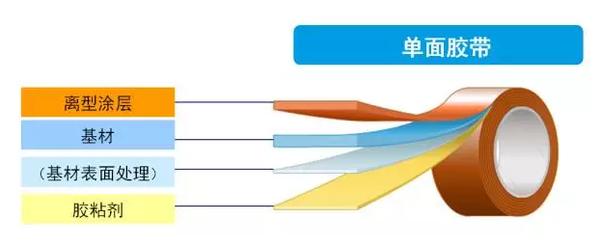

Structure of tape

Tape generally consists of a coating of various functions. The adhesive is applied to one or both sides of the substrate (to make single or double sided tape). Duct tape can be divided into three basic categories by structure:

1. Single-sided Tape, meaning only one side is coated with adhesive tape.

(2) Double-sided Tape, which is coated with tape on both sides.

(3) Substrate free Tape, that is, tape without substrate, only composed of release paper directly coated with adhesive.

Surface treatment of double-sided tape

Adhesive surface must be clean, dry, smooth, no rust and oil. During operation, fingers should be avoided from contact with the adhesive surface. After pasting, pressure should be applied to ensure full contact with the adhesive surface.

(1) Polish properly first. It is recommended to use clean flannelette to remove rust, increase the micro-contact area and improve the bonding effect.

② On the general surface, it is recommended to use the mixture of isopropyl alcohol liquor (IPA) and water (mixing ratio: 1:1) to clean oil and dust.

③ Use a clean cloth or paper towel to clean and dry the adhesive surface.

(4) For some roughness is very large, mesh a lot, extremely easy to wet (such as glass), will produce chemical reactions (such as brass) surface, need to be pretreatment, it is recommended to use base coating agent.

pressure

(1) Adhesive with small area: In order to achieve good adhesive effect, certain pressure must be applied to the adhesive tape and the adhesive surface, so that the adhesive tape and the adhesive surface are fully in contact with each other. It is recommended to use a scraper or roller.

② Large area, long span adhesive: In order to achieve good adhesive effect, the adhesive tape and adhesive surface must be applied a certain pressure, so that the adhesive tape and adhesive surface fully contact, and the average weight pressure for 12 hours, to increase the adhesive tape and adhesive surface contact, or the average clamp, so that the adhesive tape and adhesive surface full contact.

The adhesive pressure is 25PSI: the adhesive tape must be in full contact with the material to be pasted. It should be used on severely uneven surfaces.

time

Double-sided tape has initial adhesive force, 24 hours of initial curing up to 80% of the hardness, but it takes 72 hours to reach the maximum strength, during this period, do not make structural operations.

The temperature

The operating temperature of double-sided tape should not be lower than 10℃, because the temperature is too low, the initial adhesive force of the tape is greatly reduced, resulting in longer curing time.

If the temperature is too low, the adhesive materials and tape can be moved to a warm room before operation for storage or heating treatment, or use low-temperature operation type of ultra-strength double-sided tape.

If the construction requires immediate structural operation, it can improve the heating temperature of the adhesive and the tape, about 50-70℃. Heat for about 30 minutes and increase the pressure.

Common substrates:

1. Film tape (PP, PET, PVC) has stable size, stable chemical properties, temperature resistance (PET), transparent or white

2. Non-woven tape is fit, resistant to temperature, can be torn by hand and transparent

3. Foam tape (PE) vibration and noise reduction, suitable for rough surface, can compensate the thermal expansion and contraction between different materials (such as glass and metal), black or white

4. Cloth/fabric tape is fit, crack resistant, hand tear, high adhesive amount

5. The different adhesive of asymmetrical tape is coated on both sides of the substrate, so that both sides have different stripping force

6. No substrate tape No substrate, only adhesive attached to the release paper, excellent adhesion, very thin

Types of adhesives

The amount of adhesive coating (g/m2) and the formula depends on which applications the tape is designed for. Common adhesives are acrylic adhesive, natural rubber adhesive and synthetic rubber adhesive. Different adhesives have different basic characteristics, acrylic adhesives are usually more suitable for permanent and outdoor applications.

Type of release paper/film

The type of release paper material determines its physical properties, such as tensile strength, elongation, tear resistance, wet stability, cutting debris...... The release force of the paper/film should not be too large to cause the difficulty of tape stripping, nor should it be too small to fall off when touched.

Common release paper/film

Cellophane, PE coated paper, MOPP film, PET film

About

company introduction Honors Corporate VisionApplication

E-commerce packaging Use at home Office space Use of warehouse Factory floor Express delivery logisticsProduct

BOPP tape semi-finished master roll Finished duct tape Degradable adhesive tapeNews

Company News Industry Trends Encyclopedia of ProductsCopyright@2022 Huangshan Tianma Technology Co., LTD